Those of us who have been pushing solid state lighting for the past six-plus years are used to preaching about its benefits of high efficiency, fine optical control and expected lifetimes greater than anything else available. Why? Because from A-lamps to area lights, we need to communicate an intrinsic benefit to asking for the 2X-20X premium over the incumbent technology. Outdoor lighting specifications, which have been predominantly based on HID sources, are quite rapidly changing to solid state lighting because a solid ROI can be communicated on those three aspects. It’s a tougher case for solid state lighting in conditioned interior applications where the efficient (and inexpensive) linear fluorescent is currently king. Solid state lighting manufacturers rely on the newly-attainable efficiency gains over fluorescent luminaires as the primary value proposition. However, a rumbling of lumen maintenance claims as high as L90 are beginning to emanate from lighting manufacturers in an effort to add value to interior solid state lighting. Is this all smoke and mirrors, or is there legitimate value for a L90 lifetime specification?

LED lifetime for general lighting applications is traditionally defined as the L70 lumen maintenance point, at which time the light output has depreciated 30 percent from its original value. The industry settled upon this point for defining lifetime because it represented the threshold of the human eye for detecting reductions in light output. Was this a little overzealous? Probably, but we needed something. At least with L70, there would be a perception of depreciation, although over the five-plus years of operation, it would be quite difficult to detect. Should L90 ever be adopted, we’re essentially declaring end-of-life before the eye can ever see a difference! Pretty ironic indeed.

Admittedly, this is not new. L90 is clearly in response to the newer 800 series T8 lamps that are claiming L90+ lumen maintenance over 40,000 hour-plus periods. Should this be the benchmark? Let’s keep in mind that these values are really only possible on a bench top. A T8 lamp produces its peak lumens at a 25°C ambient and a T5HO at 35°C. The problem is, the luminaire enclosure, surrounding optics and environmental ambient rarely, if ever, keeps the lamp even close to these temperatures! A brand-new linear fluorescent troffer or suspended direct-indirect could, in-fact, begin its life well below L90, but this fact can be hidden in relative photometry. Did we care (or even notice) then?

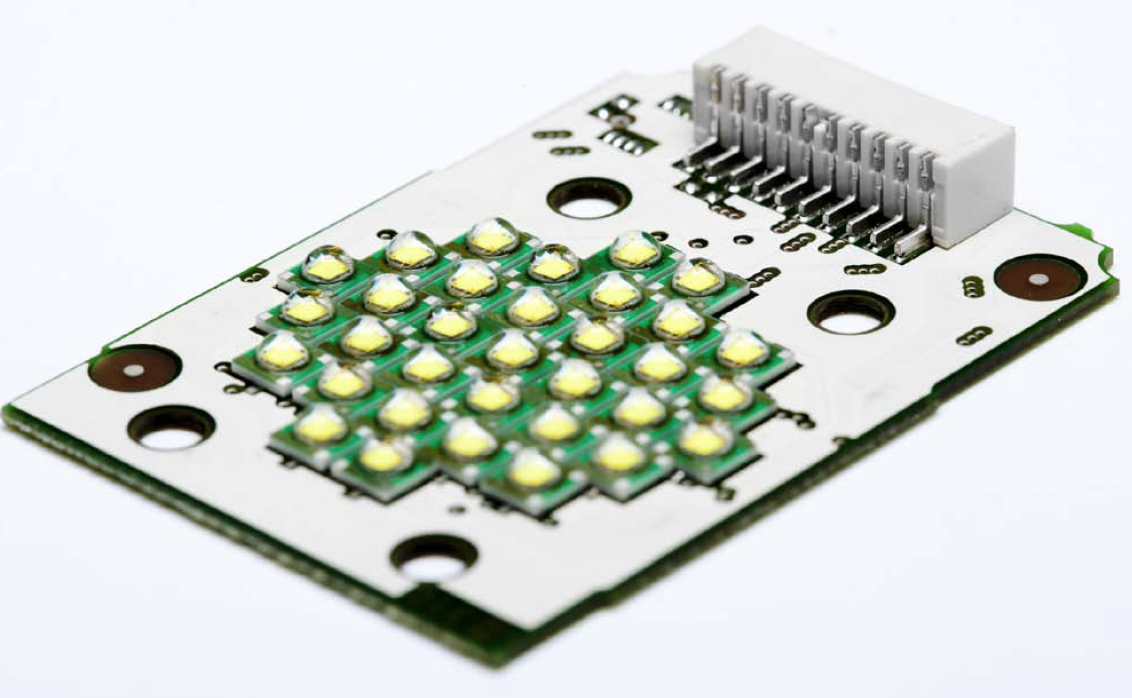

The temperature dependency of LED sources is why absolute photometry is specified by IESNA LM-79. It certainly provides for more accurate light output from the luminaire, but it is not without its own demons that will be problematic for a legitimate L90 specification—that necessary evil known as binning. Despite the diligent efforts of LED manufacturers to control their processes from die fabrication to packaging, all LEDs have some variation in terms of chromaticity and flux that must be tested and quantitatively grouped, or binned, into a predetermined range of values. This range of values is usually a 10 to14 percent variation on flux. The luminaire manufacturer then procures the LEDs to that binning specification, which will contain discrete LEDs of all values in-between. On top of that, every LED manufacturer claims a measurement tolerance of 5 to 7.5 percent on their flux measurement. All of this potential variation together means it’s very possible that a brand new LED luminaire will leave the factory well below L90!

Whether or not the products ship out of the factory at full output or below L90, there is a high probability that it will not be caught and relamped. Why? Because the only approved method for assessing LED luminous flux will be to test each product in an integrating sphere by a laboratory certified to conduct LM-79 testing. To that extent, products will likely not even undergo a re-lamping at L70 since it’s still not to a point where users will find the lighting uncomfortable, let alone any clear indication that end-of-life has been reached. Lumen maintenance is not a definite point in time that can be marked with a calendar—it’s a function heavily dependent on tens, if not hundreds, of variables not accounted for in any end-of-life projection.

L90 sounds really appealing on paper, whether it’s LED or fluorescent, especially within the game that is specification lighting. When initial output and end-of-life lie so closely together and warranties are established around those qualities, that manufacturer is accepting a very high degree of risk in order to capture a bit of attention. We can’t fault them for that, but let’s have a realistic expectation of what the technology is capable of providing and make sure there is actual value provided that offsets the risk. This isn’t uncharted territory.

:max_bytes(150000):strip_icc()/186025674-F-56b005dd3df78cf772cb2324.jpg)