One of the often-cited advantages of LEDs over tungsten filament and fluorescent lights is their high efficiency. A good quality white LED can convert around 40 percent of the electrical energy to light. While this sounds impressive when compared to other light sources it still means 60 percent of the electricity is wasted as heat. Of LEDs that work in the visible spectrum green devices are the least efficient, maxing out at around 20 percent, while UVC LEDs struggle to achieve double figures.

The heat produced by LEDs has to be removed by conduction. Failure to do so gives rise to problems with the quality of light produced and operational lifespan. The conventional solution is to mount the LEDs on a metal PCB and use a suitably large heat sink to dump the heat to the atmosphere.

Greener LEDs, Greener Flora

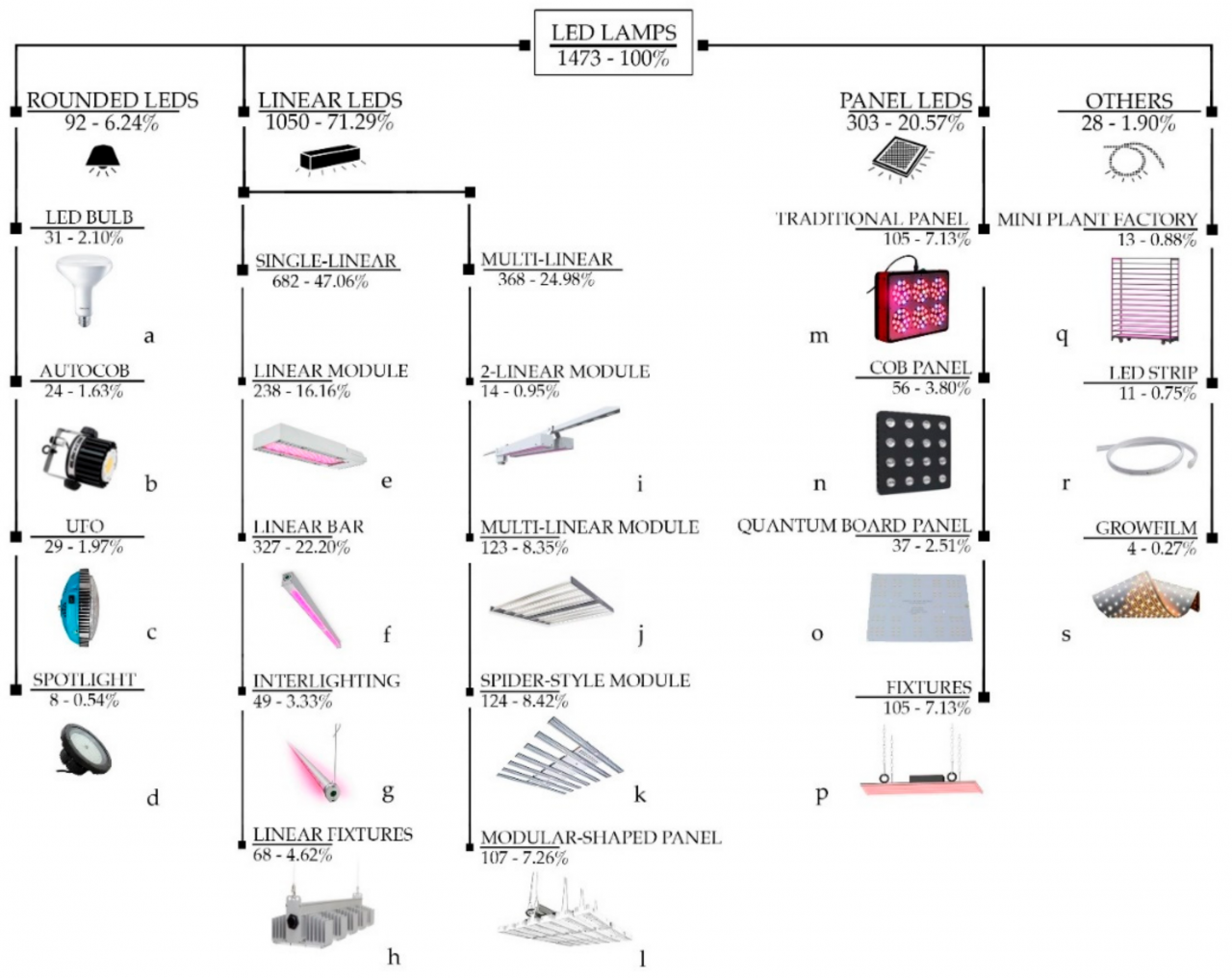

A new and rapidly increasing opportunity for LED lighting is in horticulture. While we all know that plants need light to grow (with the possible exception of mushrooms), scientists are just beginning to understand how to tune the light spectrum through a plant’s lifecycle to alter factors such as growth rate, crop yield, color and even taste. Some scientists have even predicted LED lights used in this manner will trigger a revolution in horticulture. Perversely, one of the few wavelengths plants do not respond strongly to is green, so the poorer efficiency of 560 nm LEDs is not an issue in this application.

Installing banks of LEDs in greenhouses and sheds might seem like a good idea until the electricity bill for the first month arrives. High brightness, tunable spectrum LED lights are expensive to run, particularly when lit 24×7. But light is not the only energy requirement. Many plants grow better when cosseted and in particular when the roots are kept warm. So not only does the plant growing space need to be expensively lit, it needs to be expensively heated as well.

Electricity-to-Lumens Conversion Does Not Mean Efficiency

When talking about LED efficiency lighting engineers always talk about conversion of electricity to lumens — with good reason because lights need to produce light! However, when you look at system efficiency, LED lights are 95+ percent efficient if you define the outputs as light and heat. Therein lies a stroke of genius. LED lights need to be cooled and the plants under the lights need their roots to be warmed, so why not use water to cool the LEDs and pump the warm water through pipes in the soil?

This approach has multiple advantages. Water is a much better cooling agent than air so manufacturers can make LED lights smaller, lighter, cheaper and more intense. The bits of the plant that need to be snuggly and warm are provided for and the requirements for insulating and air conditioning the growing space are greatly diminished. In one stroke, the system efficiency has leapt from unacceptable to brilliant. All the waste heat from the LEDs is recycled in the factory, rendering it eminently green.

With any new technology, the early adopters tend to be high-value products where the risk can be offset by the potential financial reward. Therefore, it’s likely to be a few years before you can buy a supermarket lettuce grown under LED lights. However, should you be partial to the occasional leaf of hippie lettuce, purely for medicinal purposes and only legal in certain jurisdictions, then the product will quite possibly have been grown under LED lights. Cool huh?