:max_bytes(150000):strip_icc()/186025674-F-56b005dd3df78cf772cb2324.jpg)

Artificial lighting has been one of the most valuable technologies ever invented and commercialized, beginning with oil lamps in c. 4500 BC, street lamps in 900, Edison’s incandescent bulb in the 1870s and LED today. Now, with the widespread adoption of LEDs, lighting is again pushing technology, functionality, comfort and now energy efficiency forward to improve our daily lives. Despite the vital role glass has played for centuries as a valuable component of artificial lighting, however, it has been missing during the LED generation and gone largely unnoticed.

Infographic by Designbysoap

Glass has been a constant presence in lighting since lanterns and street lamps first appeared on the scene in the 1700s, providing protection to both the lighting source (oil or gas) and those in close proximity to it, creating both a functional and safe solution. The incandescent bulb came along at the start of the 20th Century, becoming the essential shroud around this new jewel of lighting that would dominate and reinvent the world over the next 100+ years, providing an inert vacuum environment to protect and sustain the lighting source for long life and reliability. With the commercialization of high-performance High-Intensity Discharge (HID) and Mercury vapor commercial lighting technologies, such as High-Pressure Sodium and Metal Halide in the 1950s, glass served an added protective function along with projecting the light source. Glass was then and is now a translucent, durable material with the ability to provide light transmission while offering long-term protection to and from a light source emitting high levels of Ultraviolet (UV) and Infrared (IR) energy that would easily degrade a lesser material. In addition, the thermal strengthening or tempering of glass provided and extra measure of safety in case of breakage in the field. This partnership of light source technology and glass allowed for HID-based commercial lighting in applications such as sports and entertainment; roadway, street and area lighting; and industrial areas to flourish for the next 50 years.

At the turn of the century, as it happened a century earlier with Edison, an exciting new lighting technology began to make its way into the market. Although the first LED was invented in the early 1960s, its relevance as a viable commercial lighting source did not appear until the early 2000s with high-brightness GaN LEDs on silicon substrates. Not since Edison’s incandescent bulb have we have seen such a technological revolution and paradigm change in the lighting industry. LED lighting offers superior performance, flexibility, and energy efficiency for a wide variety of applications. Ironically, production of Edison’s original technology is now in the final stages of phase-out in the United States, and the LED is poised to be the incumbent technology going forward.

However, a funny thing happened along the way to LED lighting’s dominance – glass was left behind.

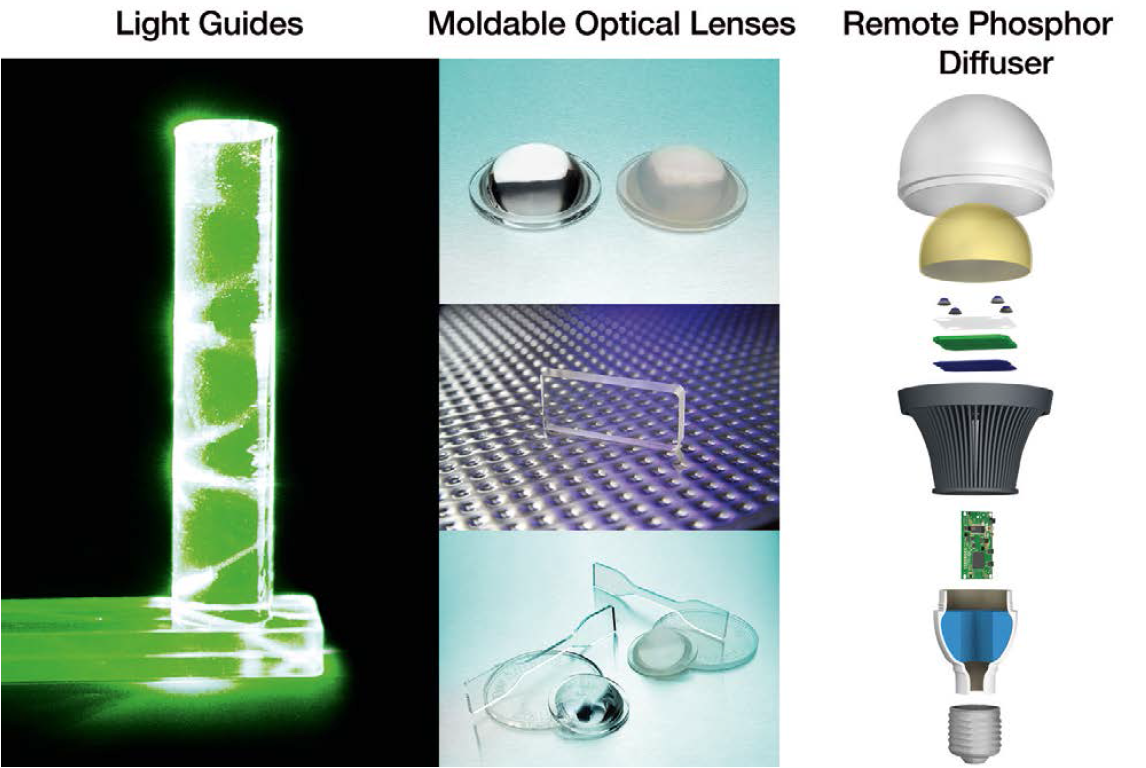

Unlike traditional incandescent and HID light sources, LED as a light source in a luminaire:

- Generates its illuminance pattern combinatorially from an array of individual point sources of light (LED chips) patterned together with individual optical lenses instead of one single source (bulb) and a reflector array with a single lens

- Does not generate high levels of UV and IR energy that degrade many translucent lens materials.

As a result, many lighting designers and luminaire OEMs have elected to field LED-based fixtures with only plastic lenses (acrylic, polycarbonate, etc.), with the belief that glass is no longer a necessary component of a luminaire – even for outdoor applications. The common belief is that glass no longer provided a tangible benefit in the field vs. plastics – especially in LED lighting, where UV and IR energy levels are low. Another argument is that a glass lens decreases the efficiency of a luminaire due to reflection losses.

On the contrary, history has shown glass to be the best long-term lens material choice for commercial lighting applications – especially those in outdoor or industrial environments. Glass protects the valuable components of the luminaire (light source, optics, drivers and ballast) from environmental elements – regardless whether it uses HID or LED technology. Unlike standalone plastic lenses, glass:

- Does not carry a static charge which attracts dirt and debris, resulting in the depreciation of the luminaire over time

- Is mechanically and chemically durable to resist degradation due to scratching and salt water exposure along coastal areas, and yellowing due to environmental UV exposure

- Can be thermally or chemically strengthened for safety in case of breakage

- Is a low-cost and readily available material option

- Can be modified through glass chemistries (low iron), applied coatings (anti-reflective, conductive, etc.) and surface treatments (acid-etching, patterning, etc.) to optimize optical performance.

History has taught us that no material is perfect. However, throughout the history of lighting, glass has repeatedly proven to be a worthy, valuable and reliable product for a variety of light sources. When paired with LED lighting and plastic-based primary optic lenses, glass can indeed provide even more differentiated value into the same commercial lighting applications it has for more than 100 years. In the blogs ahead, I will discuss in more detail the innovative ways the industry can use glass as a lens material in this new and exciting world of LED-based lighting.