Introduced to the market more than 50 years ago to connect the printed circuit boards of early computer systems together, card edge connectors have remained relevant and continue to be employed in a wide range of modern technology, including solid-state lighting. Originally used to facilitate connections between mother and daughter boards, card edge connectors also established expansion slot standards for PCI, PCI Express, and AGP cards and served as the basis for early consumer video game cartridges. Since then, card edge connectors have evolved to keep pace with the technological developments that have reshaped the electronics industry over the past half-century. Consisting of a single female connector that mates to exposed PCB contact pads processed into the edge of a mating printed circuit board (hence the name), card edge connectors continue to be modified to suit modern applications for three main reasons: simplicity, reliability, and cost effectiveness.

As the electronics industry evolved over the past few decades, card edge connectors were constantly challenged towards higher pin counts and higher signal speeds capable of supporting computer signal level advancements, which was a natural design progression. More recently, however, modern applications like solid-state lighting challenged card edge connectors to provide increased current and voltage levels capable of supporting industrial level performance, the complete opposite of the electrical specifications they were originally designed to provide, so that the rapidly expanding SSL industry could take advantage of the technology’s proven reliability while also making strides toward satisfying cost-competitive consumer product pricing demands. Due to the inherent simplicity of card edge connector designs, these specifications were primarily achieved by altering the contacts, which are the key to any reliable and robust connector system.

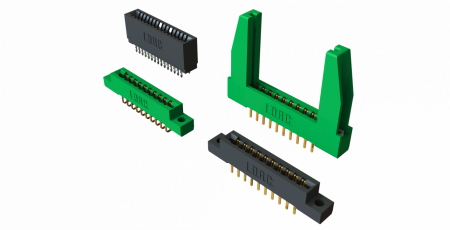

Figure 1. AVX 00-9159 Series single piece inverted through board card edge connectors mate perpendicular PCBs to a top-mounted main FR4 or metal core PCB from the bottom side, which is a common configuration in the LED bulb market. Available in two to six positions, they also offer added design functionality, such as color control or specific control lines.

Traditional card edge connectors were made with high spring force contact materials designed to accept multiple mating cycles and compensate for a larger tolerance range of mating PCB thicknesses. Newer card edge connectors designed for use in SSL applications have been developed using beryllium copper (BeCu) contact materials and are often stamped and formed to create the final contact geometry. BeCu has proven to be the best contact material on the market in stamped contacts, providing high spring force without yielding to the elevated temperatures, a large contact deflection range, substantial insertion force tolerance, and long-term reliability. One example of a BeCu card edge connector created specifically for SSL applications is AVX’s 9159 series vertical top and inverse mating connectors for perpendicular applications. Featuring a gold-to-gold active contact mating interface to maximize the mechanical and environmental performance of the connector system, 9159 series connectors provide a minimum of 10 mating cycles while supporting a UL rating of 2A per contact and 300V. Advantages that stamped and formed BeCu card edge connectors like these provide over conventional SMT card edge solutions include: multiple position offerings, up to twice the position density and current capacity, higher voltage ratings, compatibility with several PCB thicknesses, higher maximum operating temperatures, and improved electrical characteristics. Some newer card edge connectors for SSL applications, including the 9159 series, also offer optional versus integrated safety caps to achieve height reductions of up to 33 percent, which makes them much less likely to interfere with light output—a primary concern in SSL designs.

Figure 2. AVX 9159 Series card edge connectors feature gold plated BeCu spring contacts, which provide high spring force without yielding to the elevated temperatures, a large contact deflection range, substantial insertion force tolerance, and long-term reliability.

Other card edge connectors designed for use in SSL applications utilize phosphor bronze contact materials, which are slightly cheaper than BeCu contacts, but have a smaller deflection range. These contacts tend to use edge stamped contact technologies instead of traditional cantilever beam technologies and do not require any secondary forming. Much more rigid than cantilever beam contacts, phosphor bronze edge stamped contacts exhibit a high spring force with a lower spring deflection range, which requires tighter tolerance mating PCBs. Additionally, due to their high force, the number of mating cycles for edge stamped contacts is typically reduced to somewhere around five, or roughly half that of stamped and formed BeCu contacts. Phosphor bronze contacts and edge stamped technology are not new to the interconnect industry. Phosphor bronze is widely used in myriad applications, and edge stamped technology has long been used in FFC/FPC and other card edge configurations. Due to the high/rigid force that these contacts provide, tin plating is often used as a lower cost alternative to the gold plating used for BeCu contacts. The key parameter in any tin-to-tin contact interface is the amount of contact force required to both wipe the contact surface clean during the mating process and to maintain that force throughout the life of the product, which is roughly three to 10 times the force required of a gold interface. One example of card edge connectors that incorporate phosphor bronze contacts and edge stamped technology is AVX’s 70-9159 series coplanar contacts, which is extensively employed in end-to-end strip lighting applications. The UL current ratings for this series range from 2.5 to 3A per contact and 300V depending on the density and pin count of the chosen connector.

Figure 3. AVX 00-9159 open-ended card edge connectors provide higher pin count density and a smaller footprint than existing coplanar board-to-board card edge connectors, reliably connecting two PCBs in a cost effective, assembled solution and enhancing the flexibility with which engineers can mix and match power and signal lines.

Figure 4. AVX’s 00-9159 Series standard board-to-bard card edge connector provides a simple, reliable, and low cost solution for mating PCBs end-to-end in linear SSL strip lighting. The single, stamped contacts have dual contact beams to guarantee high force on standard 1.6mm PCBs and are available in two through five positions on 2mm pitch centers and provide a 3A continuous rating.

In sum, although card edge connectors are one of the more historic connector technologies, their proven simplicity, reliability, and cost effectiveness has encouraged engineers to continually create new card edge connector products designed to meet the performance standards for a variety of modern electronics. Now broadly employed in SSL applications to connect the power and ground signals of LED-to-LED or driver-to-LED boards, a host of proven, reliable, and robust low pin count card edge connectors from a variety of manufacturers are readily available on the market. Standard product sizes typically range from 2p to 6p, and expanded sizes up to 10p, which are ideal for linear lighting applications, are also available from several manufacturers. Further, card edge connectors suited for both metal core and FR4 PCBs, which are growing in SSL popularity due to the fact that newer LEDs consume less power and generate less heat for the same light output than they did even just a few years ago, and widely available as well.