The answer is YES. Today, some US LED manufacturers have already “cracked the code” on beating the Chinese at price, while maintaining high quality. This may be surprising to many business owners, energy advisors and lighting professionals. In a presidential election year, candidates on both sides of the aisle have spoken about the benefits of increasing US manufacturing and the resulting job creation. Domestic manufacturing alone does not create economic growth if the products that are produced are not competitively priced and purchased by consumers.

The formula for competitively priced US made LED fixtures is based on several key factors:

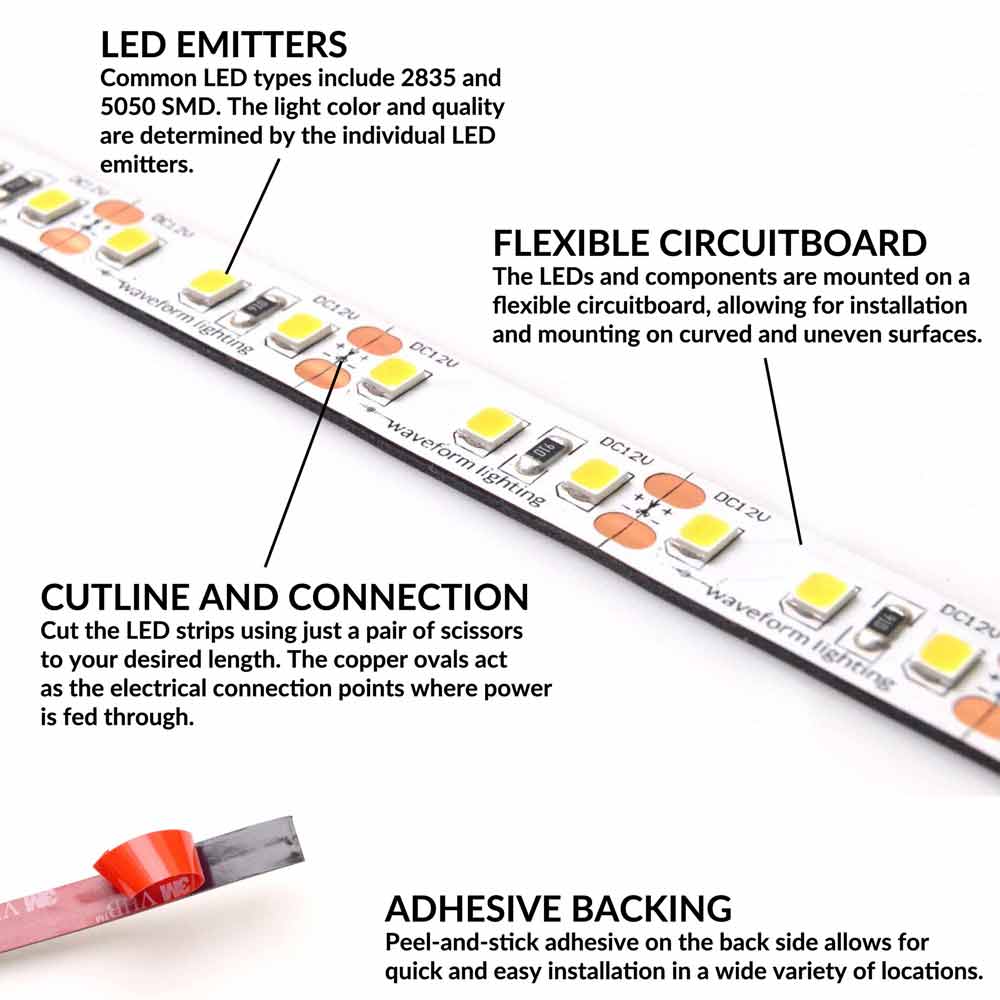

LED Automation: We have to work smarter and not harder. The Chinese labor costs are far below the US costs. So, automated technology “labor” combined with select human labor for quality assurance is key for cost control. We can also engineer the LED fixtures in modular ways to integrate with automation more cost-effectively.

LED Shipping: The “landed” cost with the US Customs cost of imported goods are surprisingly higher than most consumers would image. By making products in the US close to population hubs, like the US northeast corridor, Chicago, Los Angles, etc. the domestic products can shave off dollars that add to the cost of the Chinese imports. For large size fixtures such as warehouse high bays, the shipping cost from half way around the world is often a larger percentage of the cost than something like socket bulbs that replace the Edison lamps and Compact Fluorescent Lamps (CFLs).

LED Niches: The Chinese LED manufacturers are typically focused more on mass market volume than custom niches. So, there are “riches in the niches” for American manufacturers. As an example, there is some demand for protective impact cages on gymnasium lights at schools where students playing lacrosse may use the lights for target practice…against the wishes of their coaches. Needless to say, a high speed lacrosse ball can do significant damage to a metal halide, fluorescent, or LED light. The demand for impact resistant LED gym fixtures is much less than the mass market demand for many other types of lights. The Chinese have focused on the volume over the specialty fixtures, so their costs go up dramatically if they have to engineer a specialty application and interrupt a production line to make it. This photo is an example of an impact resistant LED high bay that is lower in cost than Chinese imports both with and without the cage. The apples to apples metric for evaluating cost is Lumens per Dollar, and this fixture wins the day.

Efficiency and TCO: The output of light relative to the energy consumed (lumens per watt) is also the default metric for comparing products. If a US made fixture has a higher lm/w than an imported fixture, it may be due to more advanced thermal management or more advanced and expensive diodes. If that is the case, the fixture will cost less to operate every month. It may cost a little bit more upfront but save more money over its life. The Total Cost of Ownership (TCO) may be lower with the US made LED fixture. Just as lm/w is a key factor in determining the lowest TCO, so too is lumens per dollar. Not all fixtures in the same “category” have the same output, so make sure to also compare what you get (lumens) for what you spend (dollars).

Warranty and TCO: Lumens per watt and lumens per dollar have a third sibling in determining the lowest Total Cost of Ownership (TCO) – Lumens per Dollar over the Warrantied life. The length of the warranty is key, as is the coverage in the warranty language. If a Chinese LED fixture has a 5 year warranty, and a US fixture has higher quality components, better thermal management, and higher overall quality controls in the manufacturing process, then the total output in lumens will far exceed the import across the life of the fixture. Time is money, so if you do not have to spend the time re-installing a fixture in five years or buying a new fixture in five years, then the US made fixture just got a whole lot less expensive than the import.

Top Tip on LED Price Comparison: If you are in the market to change your existing lights to energy saving LED fixtures, or if you have new construction projects then take a careful look at the Lumens per Watt, Lumens per Dollar and Lumens per Dollar over the Warranties life…and not just the price of the fixtures. If you are an Electrical Contractor or Value Added Reseller (VAR) providing lighting solutions, then make sure to compare the prices and the warranties, beyond just the length of the warranty coverage. If you are a lighting designer or architect, take a hard look at US LED manufacturers before making an assumption that US products are more expensive than imported Chinese LED fixtures.