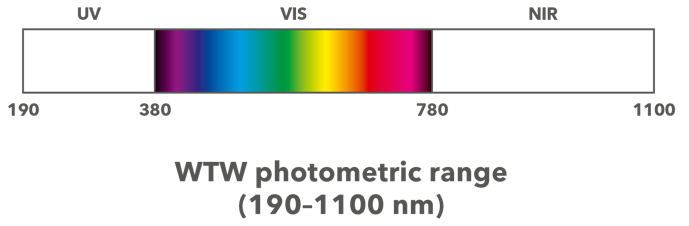

For photosynthesis, plants use more red and blue wavelength light than green light within RGB full spectrum. LED technology enables the delivery of only the wavelengths that are needed most, resulting in reduced electricity operating cost to “feed” the plants and increased ROI of plant harvests.

The next decade offers many opportunities for LED manufacturers, distributors, installers, and the whole host of energy professionals and solution providers. Saving energy and money is the key driver in the adoption of LED lights with high ROI and low Total Cost of Ownership (TCO). Low operating costs and low equipment costs move the needle. For LED grow lights, the market is about making more of something vs less of something. More plant growth often trumps energy savings!

While LEDs can reduce the operating expense over metal halide and fluorescent grow lights, the real win is when the LED grow lights can shave 10 percent or more off of the grow time to harvest. As an example with lettuce or basil, the average grow time is about 30 days, and LED lights can accelerate the growth to deliver the same harvest weight in 27 days. Over a year, the farmer can deliver 13 harvest cycles vs just 12. One more harvest is meaningful. A 20,000 sq. ft. grow operation (about half an acre and half the size of a football field) can yield over $1.5 million in basil every year. Now, LED lights are about production vs reduction.

Here are some insights about the 21st century that provide perspective on why the LED Grow Light market is poised for dramatic market growth:

The Challenges:

- Global population has doubled to over 7 billion since the first Earth Day in 1970.

- Humankind may deplete fresh water resources before running out of fossil fuels.

- In America, food travels hundreds and thousands of miles to its destination in many areas.

- America faces increasing health challenges from childhood obesity and an overweight population.

- Low-income households are at the highest risk, given limited access to affordable fresh produce.

- The developing world faces increasing food challenges, given droughts and extreme weather.

The Solutions:

- Leverage the advantages of Light Emitting Diode (LED) technology to provide cost-effective, fresh and organic produce at local levels.

Results:

- Fresh and Cost-Effective Food for the World.

LED Grow Lights = $ Money. The available LED technology and “Smart Controls” enable next generation farmers to grow indoors during the day and at night. They also reduce shipping costs to increase net profit. LEDs will reshape agriculture, because a new generation of urban farmers will use abandoned and un-leased industrial buildings to grow organic food close to the communities that will eat it. This reduces the farm to table distance and cuts the pesticides out of the process.

Not all LED Grow Light are created equal.

If you are in the market to use LED grow lights or seek to expand your sales offerings through a strategic relationship, look for grow lights that meet certain standards. Specifically, look for LED Grow Lights with highest Photosynthetic Active Radiation (PAR) per dollar for vegetation and flowering.

In addition to LED vegetation and flowering fixtures, look for manufacturers that offer custom solutions to meet growers’ needs. Modular design can deliver Photosynthetic Photon Flux Density (PPFD) at varying wavelengths to give growers a competitive advantage.

Look for external driver technology with the ability to program, through smart controls, the cycles to optimize plant growth over multiple growth sessions within a 24 hour period, based on the different types of plants.

Look for fixtures with dimming capabilities to simulate sunrise and sunset and/or to optimize plant growth over multiple growth sessions.

Look for adjustable suspension systems so that the elevation of the light source above the plants is optimized for plant growth.

Look for opportunities to integrate hydroponic and also aquaponics systems into the LED grow operations. A pound of feed may only yield an ounce of protein from livestock, while a pound of feed for fish will yield closer to a one-to-one pound of protein from a fish, such as tilapia. Plus, vegetables such as kale are nutrient rich “superfoods” with numerous health benefits: http://advancingyourhealth.org/highlights/2013/09/17/health-benefits-of-kale/

Top Tip on LED Grow Lights:

Choose a commercial LED lighting manufacturer or solutions provider that has the highest Photosynthetic Active Radiation (PAR) per dollar of fixture cost. While higher watts are a negative in building illumination, they are typically a positive with grow lights (all things equal in the wavelengths), because more watts translate into more light for plant growth. The $/watt analysis is also relevant in comparing LED fixtures if the light of the different fixtures is distributed across the grow surface rather than creating hot spots. You can look at the cost per watt as a way to short list LED Grow Lights. Just divide the fixture cost by the wattage and this is a great first line of comparison.