GaN-based LEDs find widespread applications, but they exhibit maximum efficiency only at very low current. The electrical-to-optical power conversion efficiency drops dramatically with higher input current. This so-called efficiency droop has been investigated for many years, and it still represents a key challenge to solid-state lighting, according to the DOE SSL R&D Plan published in May 2015.

Trouble is, we often don’t know for sure what causes this efficiency droop. Different microscopic mechanisms have been proposed, most prominently thermionic electron leakage from the light-emitting active layers and Auger recombination inside these layers, respectively. Droop analysis is mainly based on modeling and very few direct measurements of either mechanism are published thus far.

The first direct evidence for Auger recombination in InGaN quantum wells was provided only two years ago by measuring high-energy (hot) electron emission from the LED surface (http://arxiv.org/abs/1304.5469). The authors believe that these hot electrons are generated by Auger recombination inside the active region and subsequently travel all the way to the LED surface. Another experiment was conducted independently by German researchers based on the assumption of a much shorter hot electron travel distance (http://epub.uni-regensburg.de/28841/2/ApplPhysLett_103_071108.pdf). In that case, hot Auger electrons release their energy quickly and are captured by a neighboring active layer. However, the Auger signal is relatively weak in both cases and there is no direct evidence that the Auger process is strong enough to single-handedly cause the measured efficiency droop.

Electron leakage was first observed in 2008 on ultraviolet LEDs by measuring additional light emission from p-doped layers, which indicates electrons traveling beyond the active region. A few similar reports followed, but none was able to demonstrate a leakage magnitude that fully explains the measured efficiency droop. Interestingly, a group from Korea observed electron leakage when the LED is cooled down to cryogenic temperatures (http://dx.doi.org/10.1063/1.3703313). The blue LEDs used in this study did not exhibit any leakage at room temperature. This result was quite unexpected since we usually believe that higher temperatures make it easier for electrons to escape from the active region.

Advanced computer simulation was recently able to explain this phenomenon (http://www.nusod.org/piprek/piprek15apl2.pdf). Due to the high ionization energy of Mg acceptors used for p-doping, rising temperatures free more holes and improve the hole conductivity significantly. This was confirmed experimentally by a group from Finland (http://dx.doi.org/10.1109/TED.2015.2391117). As a result, the hole injection into the active layers is enhanced, fewer electrons need to leak out to find holes, and the efficiency rises with higher temperature.

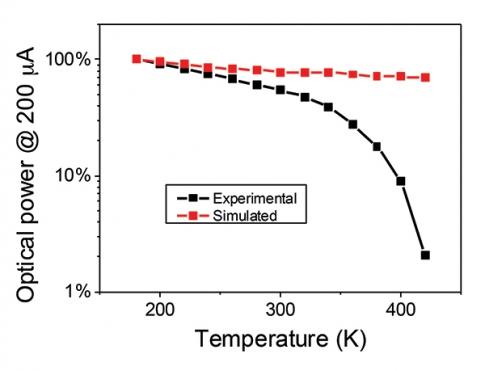

On the other hand, if Auger recombination is causing the droop, the simulations show a declining efficiency with higher temperature. Thus, the competing efficiency droop mechanisms have the opposite effect on the efficiency when the LED temperature rises. The temperature sensitivity of the LED efficiency therefore offers a simple way to distinguish between both droop mechanisms. Published measurements commonly show a declining efficiency with higher temperature. Thus, Auger recombination can be considered the primary mechanism behind the efficiency droop in these devices.

In fact, I am not aware of any efficiency measurement that shows the opposite trend, i.e., a growing efficiency with rising temperature. Please send me an e-mail if you know of such a case (piprek@nusod.org).