There are many different designs of hydrogen generators available on the Internet. There’s also many schematics available to download showing exactly how to build your own hydrogen (or Brown’s Gas) generator. While adding this component to your vehicle, keep in mind that some vehicles may not benefit from the injection of Brown’s Gas but many will – especially in smaller, older vehicles.

Vehicle Compatibility for Brown’s Gas

Some vehicles, especially newer vehicles with all the computer controls, could possibly run erratically if you introduce Brown’s Gas into the air intake system. This is primarily due to all of the sensors that are installed on vehicles today.

When Brown’s Gas is introduced into the air intake system, it enriches the quality of the air by adding hydrogen and oxygen. Vehicle engine sensors are designed to detect “normal” air quality and make any adjustments to the engine necessary if air quality changes. When they detect the hydrogen and oxygen enriched air in the air/fuel system, the computer will automatically make changes to the air/fuel mixture and cause the engine to run erratically.

Some people have avoided this problem by removing the air sensors from the vehicle and replace them with a fake sensor that makes the computer think that the sensor is still there, but unlike the air sensor, the fake sensor does not send any signals to the vehicle computer. There are also other methods to avoid this problem and a quick Internet search on “vehicle sensors and Brown’s Gas” will show ways to avoid computer issues.

The Homemade Hydrogen Generator

The hydrogen generator that you build should be designed especially for the vehicle in which you are installing it. You need room for the hydrogen generator, and it should also be located close to the battery (for power).

Components List

You will need at least the following components to start building your hydrogen generator:

- A canister large enough to contain the water, electrolysis plates, and wiring.

- At least two stainless steel receptacle wall plates.

- Grommets, plastic or rubber washers, and stainless steel screws.

- Heavy duty wires (6 to 8 gauge) – red (positive) and black (negative).

- Fuse boxes with at least 30 Amp fuses

- Enough plastic tubing to connect the canister to the fuel intake system.

- An on/off power switch to allow power to be controlled to the generator

Basic Instructions for Building a Hydrogen Generator

Many different types of containers can be used to build a hydrogen generator, but the most common is a standard 6” to 8” PVC pipe cut to the desired length. The pipe must be completely sealed to allow the gas to be contained and captured. PVC caps or threaded ends can be used for this.

The stainless steel wall plates are those used to cover an old receptacle that is no longer used. These can be found in any hardware store. Stainless steel must be used because it does not corrode as regular steel will. Electrolysis will corrode normal steel within minutes.

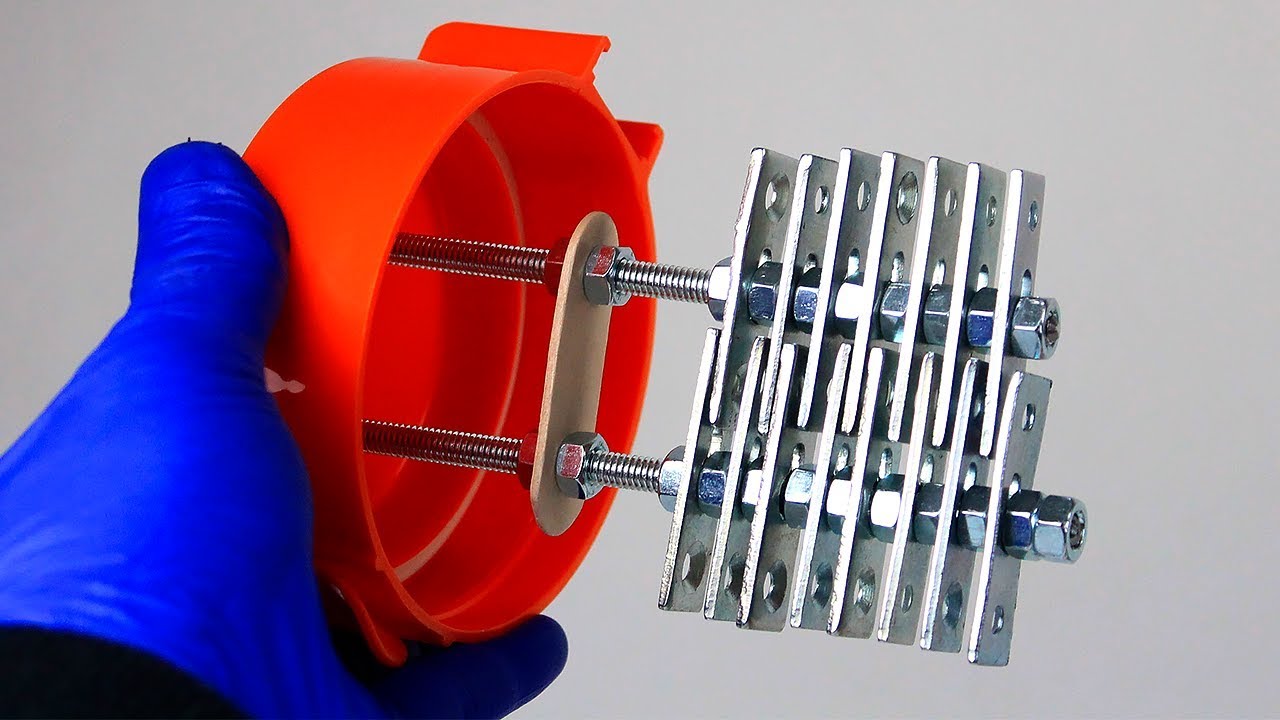

The steel wall plates should be sandwiched together but not touching. Mount the grommets inside the “screw holes” of the wall plates, use the rubber washers on the outside of the plates and attach them together with the stainless steel screws but leave each screw attaching a separate plate. The plates must not touch each other but each screw needs to touch each plate.

Connect the red (positive) wire to the screw on one of the plates, and connect the black (negative) wire to the opposite screw on the other plate. You should now have about a 1/8” space between the two plates with each wire connecting each plate. One plate serves as a positive conductor while the other plate will serve as the negative conductor. When powered, the current passes through the water within the canister – breaking down the water into its single atoms (hydrogen and oxygen).

A plastic tube (normally around ¾”) should be inserted through a drilled hole near the top of the canister where the gas will collect. It is this tube that will connect to your vehicles intake system; supplying the Brown’s Gas. As a safety precaution, connect the hose to the hydrogen generator canister and run it into a separate canister which contains water – then finally connect it to the intake system of your vehicle. This secondary canister will help prevent a disaster in case the gas is somehow ignited by the engine.

Install an on/off power switch on the inside of your vehicle – and connect to the red wire supplying power to the hydrogen generator. There’s several different ways to connect the power switch so do a bit of research on this. Also install the fuse box in-line with the power supply wire. If a wire was somehow shorted out, the fuse will blow instead of causing electrical damage or fire to your vehicle.

Connecting to the Air Intake System

Most vehicles are equipped with a rubber type, air-intake component which connects from the vehicles air filter directly to the engine intake. It is this rubber component where you will want to connect the tubing from the hydrogen generator. When the hydrogen generator is operating, pressure will build inside the container – which will force the gas into the engine’s combustion chambers.

More Information on Building These Systems

By no means can this short article describe all of the science involved in building a Homemade Hydrogen Generator. It was written to cover the very basics of this component and to give you a brief idea as to how they work and connect to a vehicle. I’ve included several links below that should be reviewed before attempting to build your own hydrogen generator.

And remember; take caution when building these because they can explode!